There are many different types of handsaws available, each designed with a particular material or cutting surface in mind. One of the most important factors when choosing a handsaw is the intended application, so, in this guide to hand saw types, we’ll take you through the different varieties of handsaws on the market and teach you how to choose the right handsaw for the job.

What are Handsaws?

A hand saw is a manually operated cutting tool, designed to help you make incisions into different surface types as well as trimming materials to size.

Some of the most common uses of a handsaw include felling trees and logs, but handsaws are also a popular tool for cutting different types of construction materials, including MDF, chipboard, plywood, hardwood, softwood, ceramics, and certain types of metal.

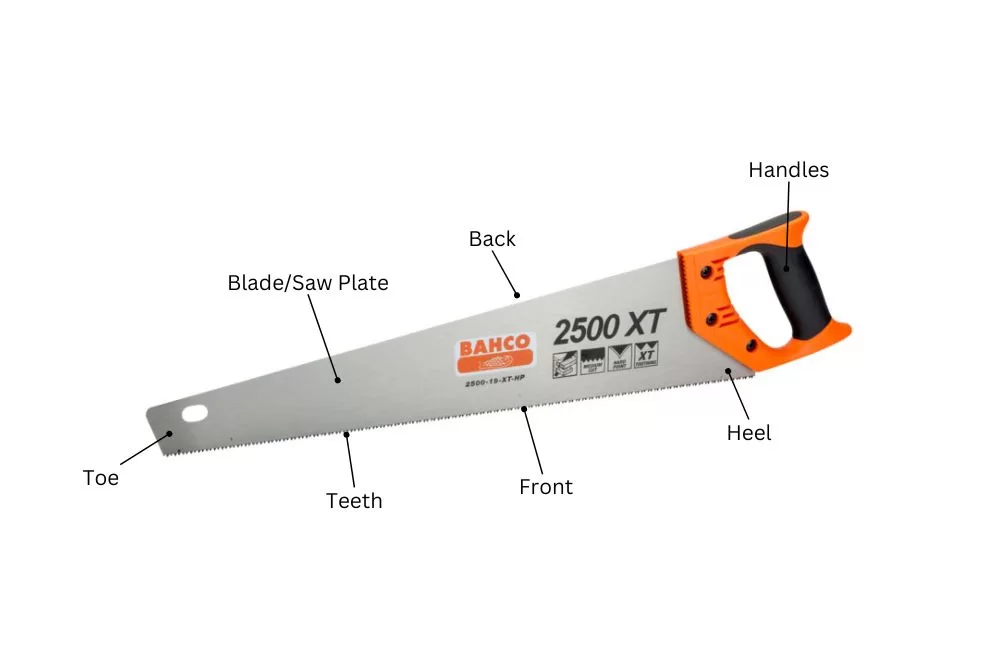

Parts of Handsaws

There are several common components to a handsaw. These range from the handle (the part gripped by the user while operating the saw) to the teeth (the serrated edge of the saw’s blade that connects with the cutting surface).

Different Types of Handsaws

Hand saws come in many varieties, from wood cutting hand saws to metal cutting hand saws. Being familiar with the different types of hand saws is the key to choosing the right tool for the job. Below we expand on some of the most common hand saw types and their uses.

1. Hacksaw

A hacksaw is a handsaw designed for cutting metal. It has a narrow and somewhat flexible blade, which enables it to saw through metal pipes, thin metal sheeting, and even plastics.

Hacksaws can be identified by their fine-toothed blade. They typically feature a tooth density of 18 to 32 inches, tensioned between a rigid C-shaped frame.

2. Tenon Saw

A tenon saw (also known as a back saw or dove tail saw) is designed to cut hard and soft woods with extreme precision. It’s the perfect handsaw to use if you only need to make small incisions into the wood.

Tenon saws have a high TPI (teeth per inch) and a non-flexible blade which allows them to deliver neat and precise cuts, while giving the operator total control of the saw.

3. Coping Saw

A coping saw uses tension to keep the blade secured during cutting. This saw type is typically used to shape wood, in particular into coping joints – thus being called a coping saw – but they’re also perfect for cutting plastic and ceramics.

Unlike hacksaws and tenon saws, coping saws have fewer teeth on their blades, normally in the region of 15 or 17 teeth per inch.

4. Hardpoint Saw

A hardpoint saw is a basic saw type, that has induction-hardened teeth, a plastic moulded handle, and a triangular toothed blade that’s ideal for cutting hardwood, hardboard, or chipboard.

Unlike other handsaw types, hardpoint saws cannot be re-sharpened and the whole saw must be replaced once the blade becomes blunt.

5. Panel Saw

Panel saws have larger teeth and are mainly used for creating rough cuts. They have a thin and flexible saw blade, and their size makes them short enough to fit into the top lid of a panel tool chest, which is how they earned their name.

6. Fret Saw

Fret saws (derived from the French word “fretter” meaning latticework) are designed specifically for latticework.

They feature around 32 teeth per inch on their blade, allowing for the kinds of extremely precise cuts that are essential for complex woodworking.

7. Compass Saw

A compass saw is primarily used to cut curves in sheet material. It has a long rigid blade, with a TPI of around 11, and operates best on the pull stroke.

8. Pruning Saw

Pruning saws are a common type of garden tool for trimming tree branches and bushes. They have a distinctive curved handle, and more teeth per inch than similarly sized saws, making them ideal for tackling branches in hard-to-reach areas.

Wood Cutting Handsaws

Wood cutting hand saws cover a range of applications, from pruning and felling to furniture making, construction, and carpentry. For this reason, no single wood saw is appropriate for all jobs but, as a rule, wood saws with coarser teeth are best suited to tackling thicker and tougher material, where neatness isn’t a concern.

Conversely, if you need to cut wood more intricately and with greater precision, you should use a fine-toothed hand saw with a higher number of teeth per inch.

Metal Cutting Handsaws

One of the most trusted metal cutting hand saws is the hack saw, however, as with wood saws, a hacksaw may not be appropriate for all types of metal work.

The shape you need to achieve, and the finish quality, are just two of the factors you need to consider when choosing a hand saw for cutting metal. In addition, the thickness of the metal and the type of metal itself, will also have a bearing on whether a hack saw is the most appropriate tool for the task.

How to Sharpen a Handsaw

The duller your saw blade gets, the less precise it will cut, so replacing your saw blade or learning how to sharpen a hand saw is an essential part of hand saw maintenance.

Many tradespeople will simply choose to replace the old saw blade or trade up for a new saw, as re-sharpening is a time-consuming task that requires uniform precision. In addition, not all saw types are suitable for sharpening, so it’s important to check whether your saw can be sharpened before proceeding.

To sharpen a hand saw, you’ll need a vice block, a taper saw file, and a flat mill file. The saw should be placed in the vice, blade-first, as low as possible and with the teeth still showing.

- Keeping the flat mill file parallel to the saw blade and level across the teeth, apply a gentle pressure to each tooth in a side-to-side motion to create a flat top on each tooth.

- Next, use the taper saw file to sharpen each tooth by putting the file in between two teeth and making two or three gentle sideway strokes in the same direction.

- Once the flat top of each tooth has been shaped into a point (that’s uniform across the length of the saw blade), your saw is sharpened. If you notice any anomalies in the teeth shape or size, make sure to correct these before using the saw.

Blade Length and TPI

We’ve mentioned blade length and TPI a few times in this guide. Both are a fundamental part of a hand saw’s design and have a bearing on the type of cut that can be achieved.

Blade length

Saw blade lengths typically range from 6” to 12” and 22” to 24”, with shorter saws designed for shorter strokes and vice versa. Longer saws, therefore, require the full motion of your arm to function and (for the most part) offer greater efficiency, but they’re not appropriate for all applications.

Longer saws also commonly have more teeth than their shorter counterparts, but not necessarily more teeth per inch (TPI).

TPI (Teeth Per Inch)

TPI or teeth per inch is the unit by which saw teeth are measured. The higher the TPI the neater the finish a saw will achieve. If you need to make clean and precise cuts you’ll need a hand saw with a high TPI. If speed is more important, however, you should opt for a hand saw with fewer teeth. These cut more quickly, but don’t offer the same degree of neatness.

Popular Handsaws

At Red Box Tools we offer a wide selection of professional quality hand saws, manufactured by a range of top tool brands.

Whether you’re a tradesperson in search of a high-quality hand saw that won’t let you down or a DIY enthusiast looking to complete some home improvements to a top standard, you’re sure to find the perfect hand saw in our Red Box Tools range.

Ready to get organised?

Find your perfect tool storage from our professional range

From tool bags and tool chests to tool boxes with wheels, tool belts, tool cases, and trade-specific tool storage, at Red Box Tools we offer high-quality solutions you can count on.

Or why not take your tool storage to the next level with our made-to-order tool box foam drawer inserts and custom shadow foaming?